are covered in :

MATERIALS:Any of the following materials may be used to make rope: binder twine, bailer twine, plastic twine, jute twine, yarn, string, or plastic bags. Just about any material that is made up of long flexible strands or that can be cut into strands can be used to make rope. However, only twines of proven strength should be used to make rope that will be expected to carry a load or lash a structure. TYPE OF ROPE:The type of rope that is explained in this book is three strand laid rope. This type of rope is made by twisting three strands of fiber in one direction and then laying the three strands together by allowing the strands to twist together in the opposite direction. A SIMPLE ROPE MACHINE:

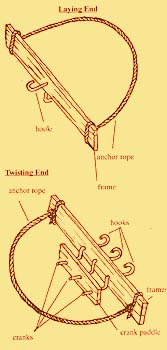

The twisting and laying can be done by hand but this takes a long time. To speed up the operation a machine is needed. A rope machine consists of two devices; one that twists the three strands, the twisting end; and one that is used to lay the twisted strands together, the laying end. ROPE WORKS has a set of diagrams showing a simple machine that can be made from scrap lumber and coat hanger wire. SETTING UP A ROPE MACHINE:After the two ends of the rope machine are positioned, tie the end of the twine to the laying end hook. Then hook the twine over one of the hooks on the twisting end, then back to the laying end hook. Continue back and forth until each of the three hooks on the twisting end have two lengths of twine on it. Be careful to keep the tension equal on all lengths of twine. TWISTING THE STRANDS:After the machine is set up, turn the cranks on the twisting end so that the cranks are turning clockwise as you are looking at the crank handles. It Is a good idea to mark this direction on the frame of the machine. Twist the strands until they become firm and resist further twisting. If the strands are not twisted tight enough the rope will be loose. On the other hand if you twist the strands too tight the strands will kink. Kinked or loose strands will weaken the rope. Experience will teach you when the amount of twist is just right. [NOTE] During the twisting the laying end must not be turned. [NOTE] While twisting and laying a modest amount of tension must be kept on the rope. LAYING THE ROPE:To lay the rope a rope-wrench will be needed. A rope-wrench can be made from a crotched stick. The actual laying of the rope is done by turning the laying end crank in a counterclockwise direction and moving the rope-wrench toward the twisting end. MAKING A GEARED ROPE MACHINE:

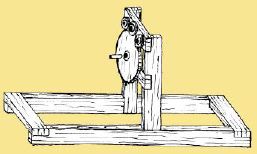

A geared rope machine not only speeds up the process of making rope but can also be used to make rope several inches in diameter. The patterns and instructions included in ROPEWORKS are for building a wooden geared rope machine that has a 3:1 gear ratio. This rope machine can be constructed with hand tools.

|